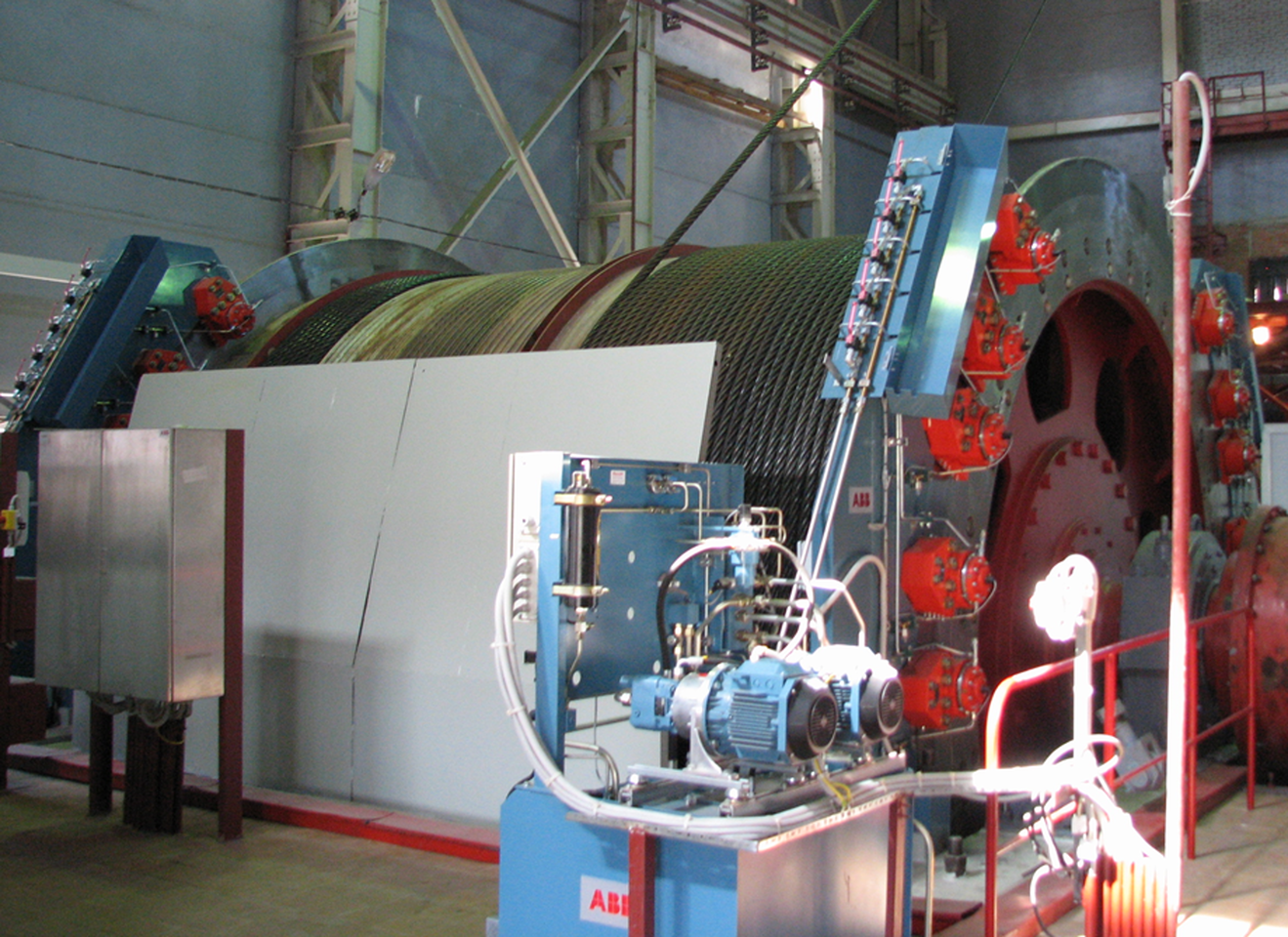

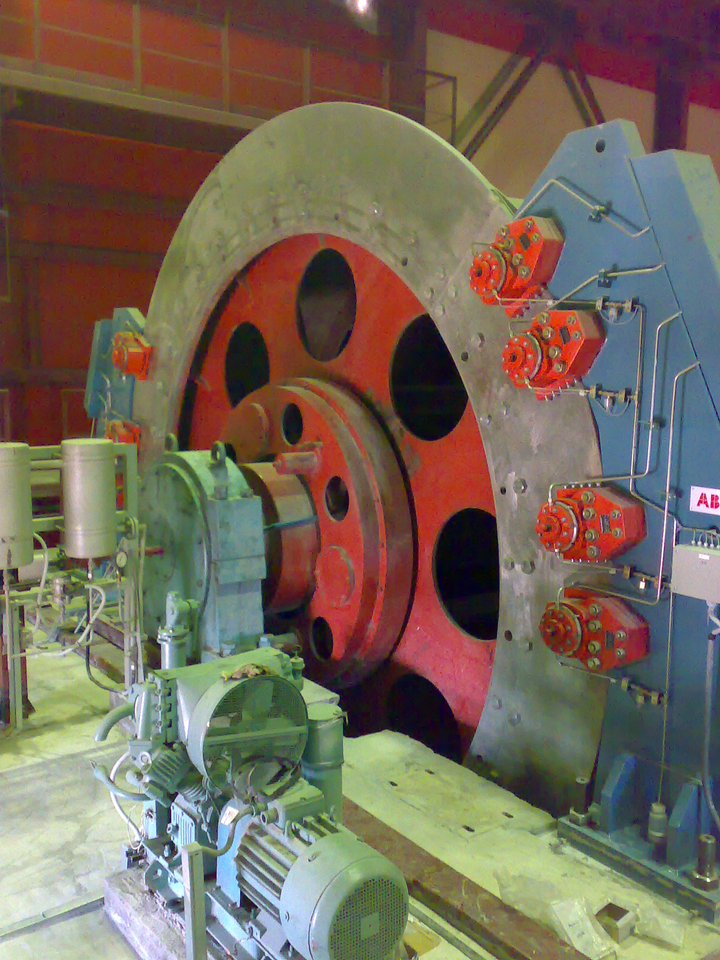

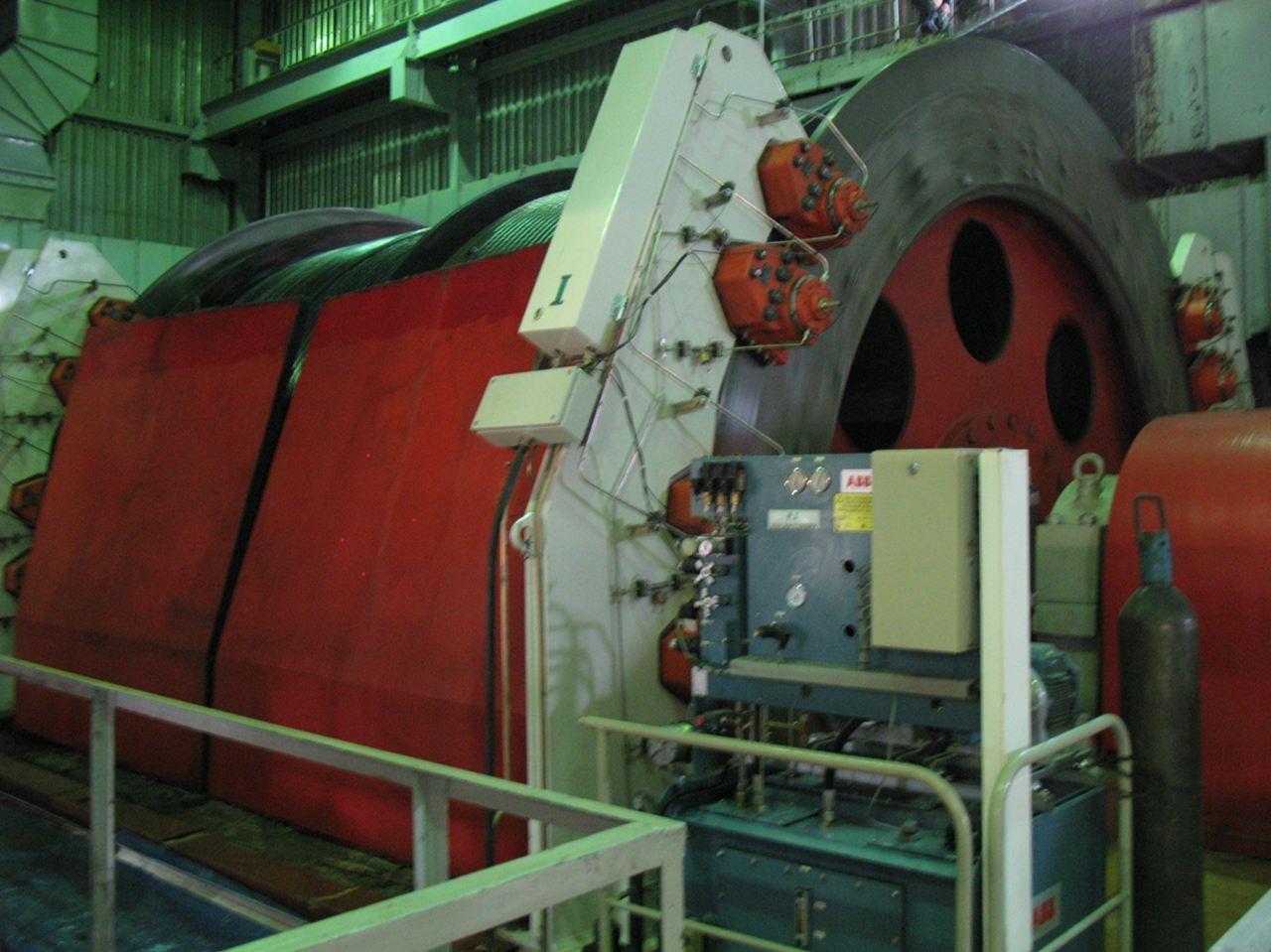

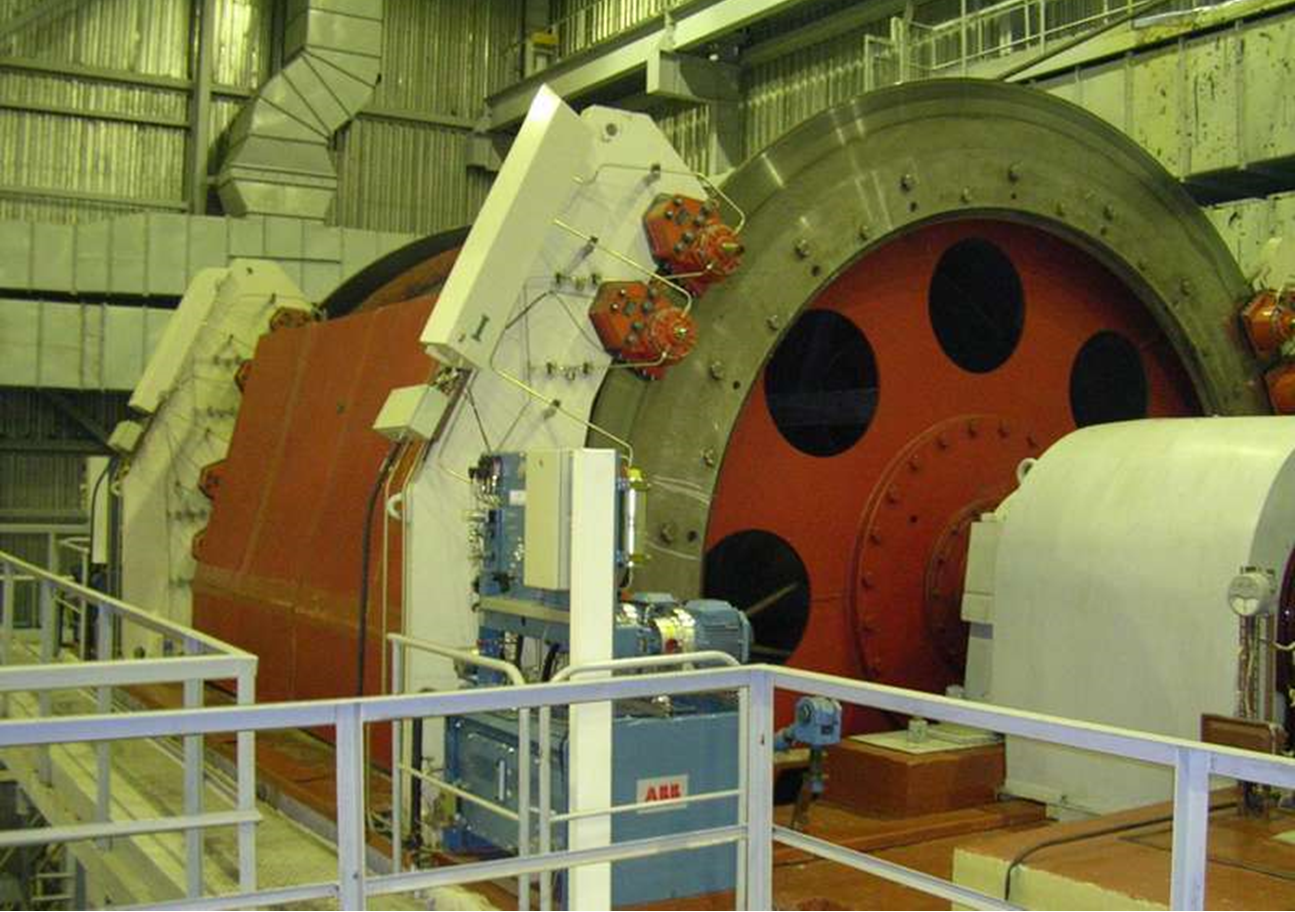

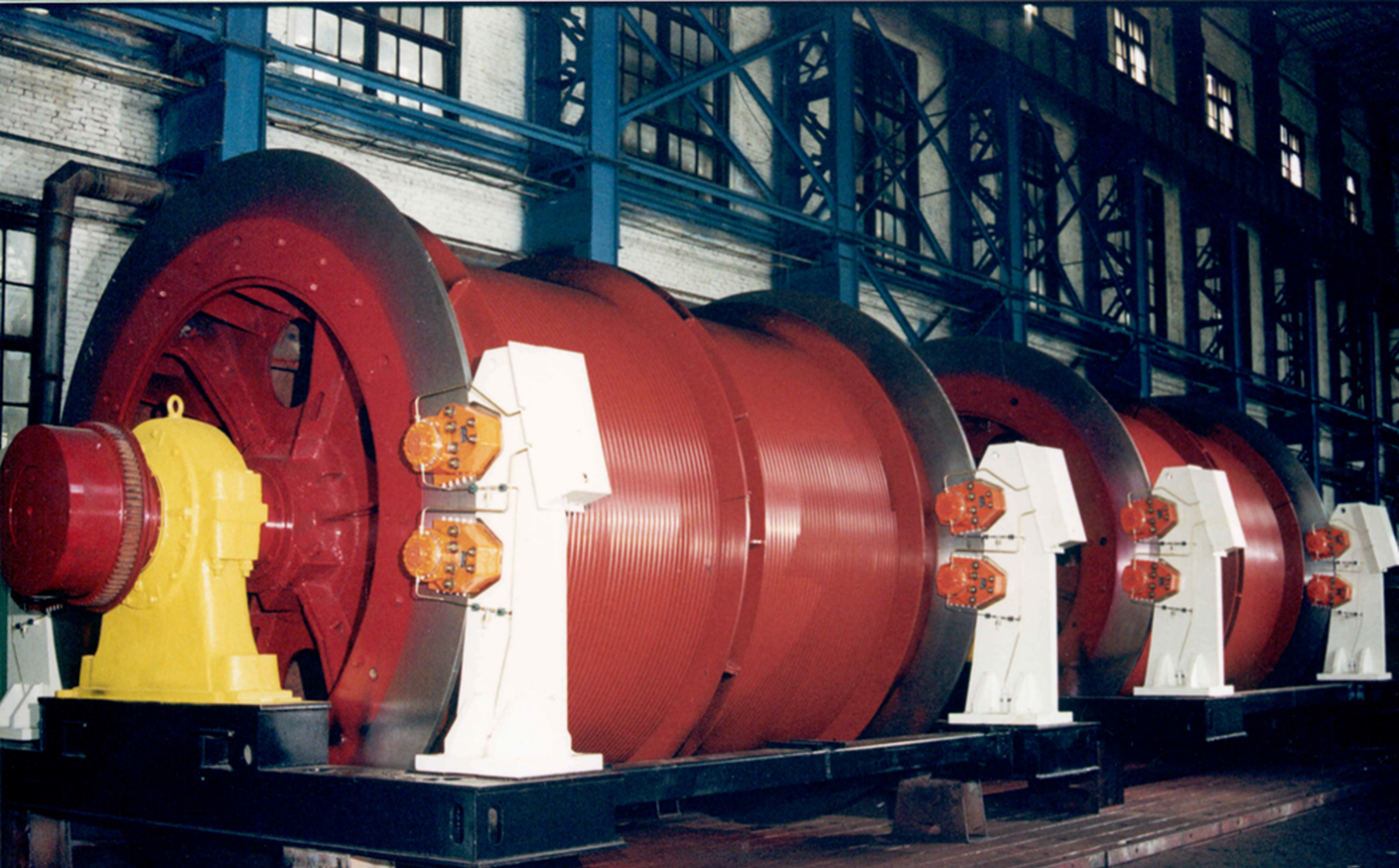

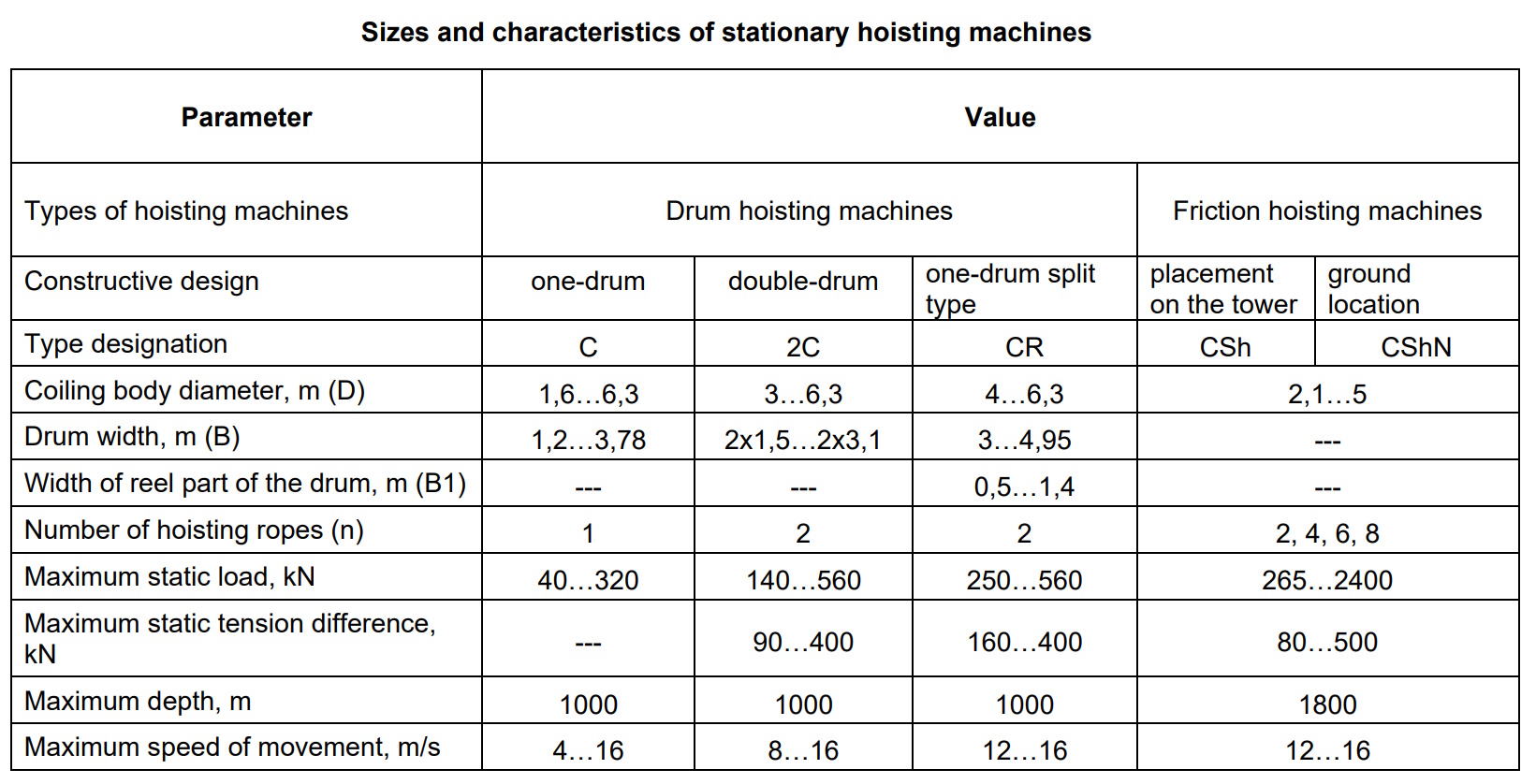

Stationary mine hoisting machines

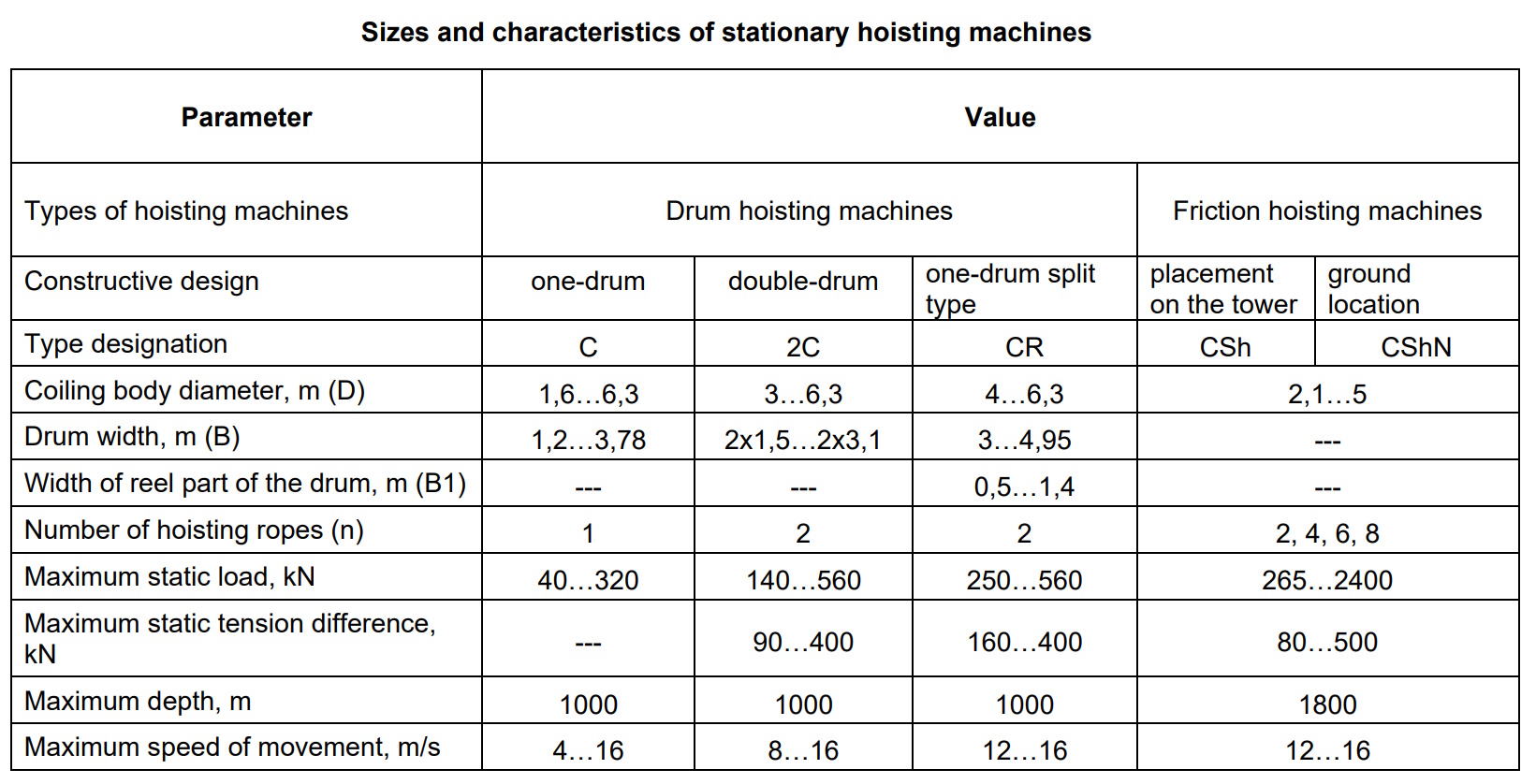

MIDIEL Group offers complete delivery of a wide range of stationary mine hoisting machines in accordance with the purpose and technical characteristics defined by the customer:

- one-drum hoisting machines;

- double drum hoisting machines;

- drum hoisting machines with split drum;

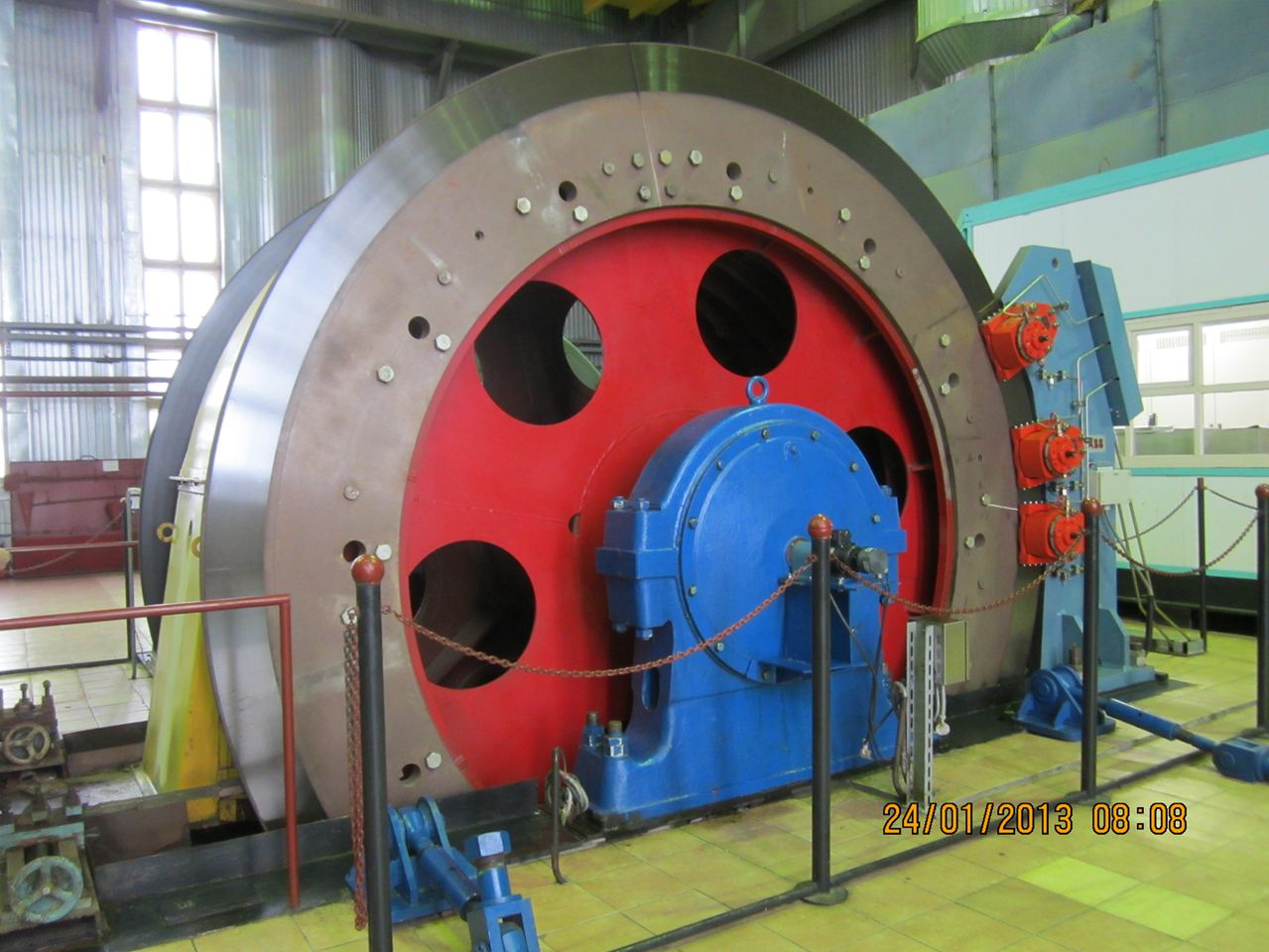

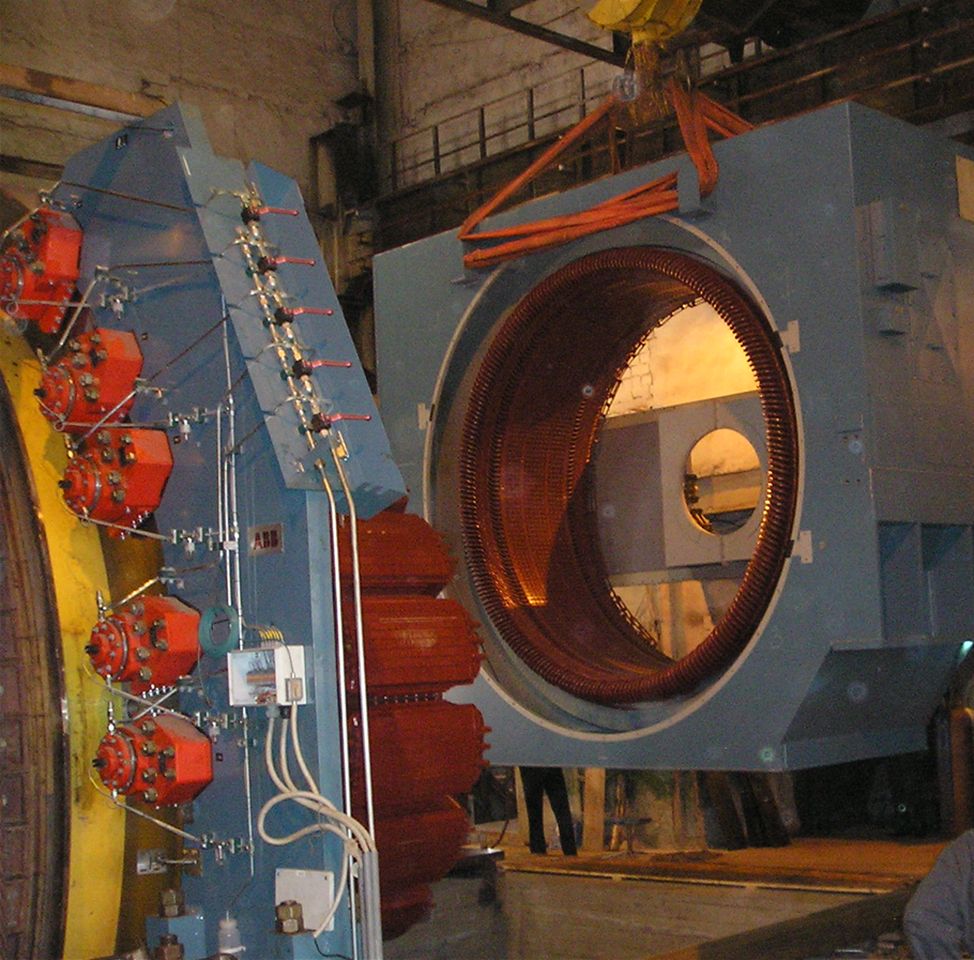

- friction hoisting machines (many-rope type) tower and ground location.

Custom-made machines, manufactured on the basis of technical specifications.

At the customer’s request, the hoisting machine can be selected from a standard size range or designed individually by MIDIEL Group to achieve optimum compliance with the required technical characteristics.

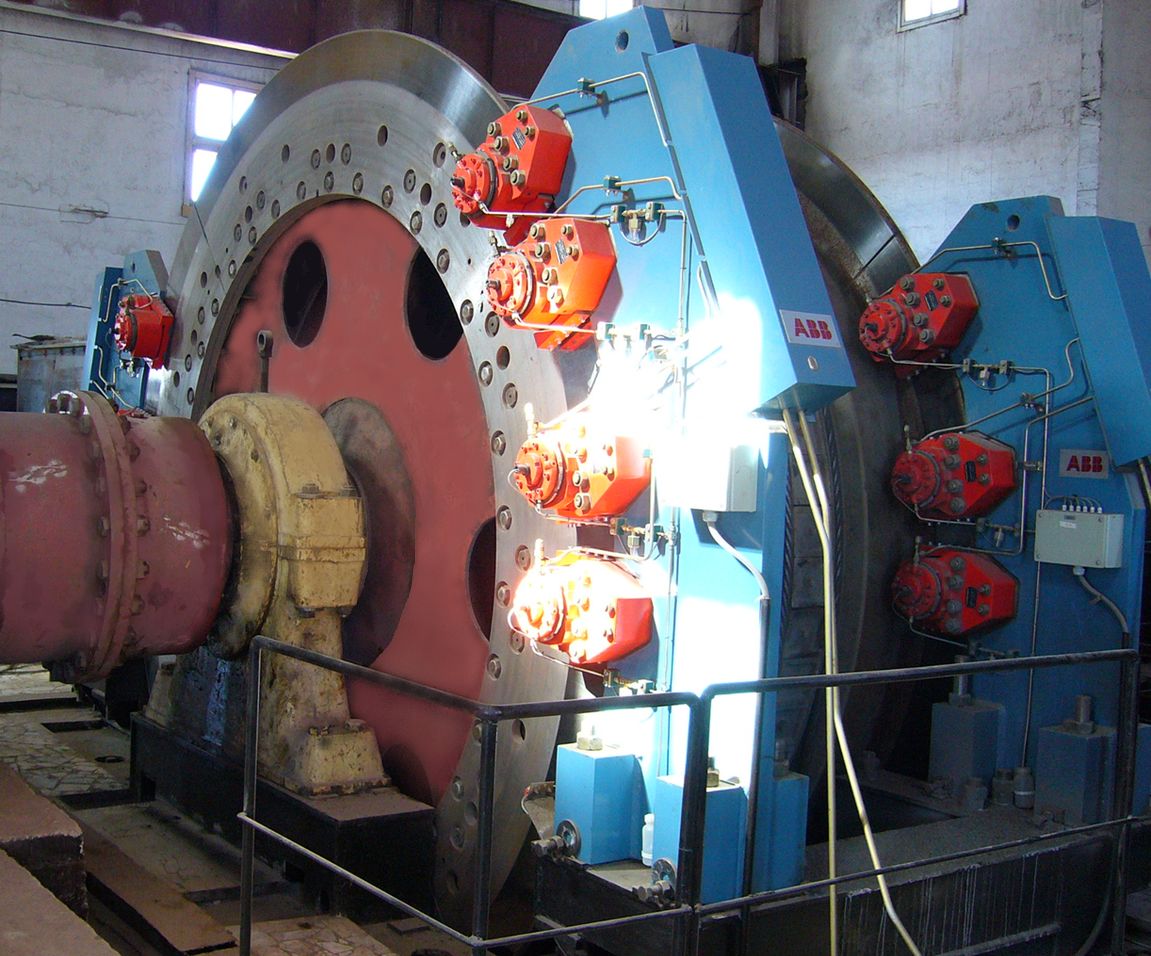

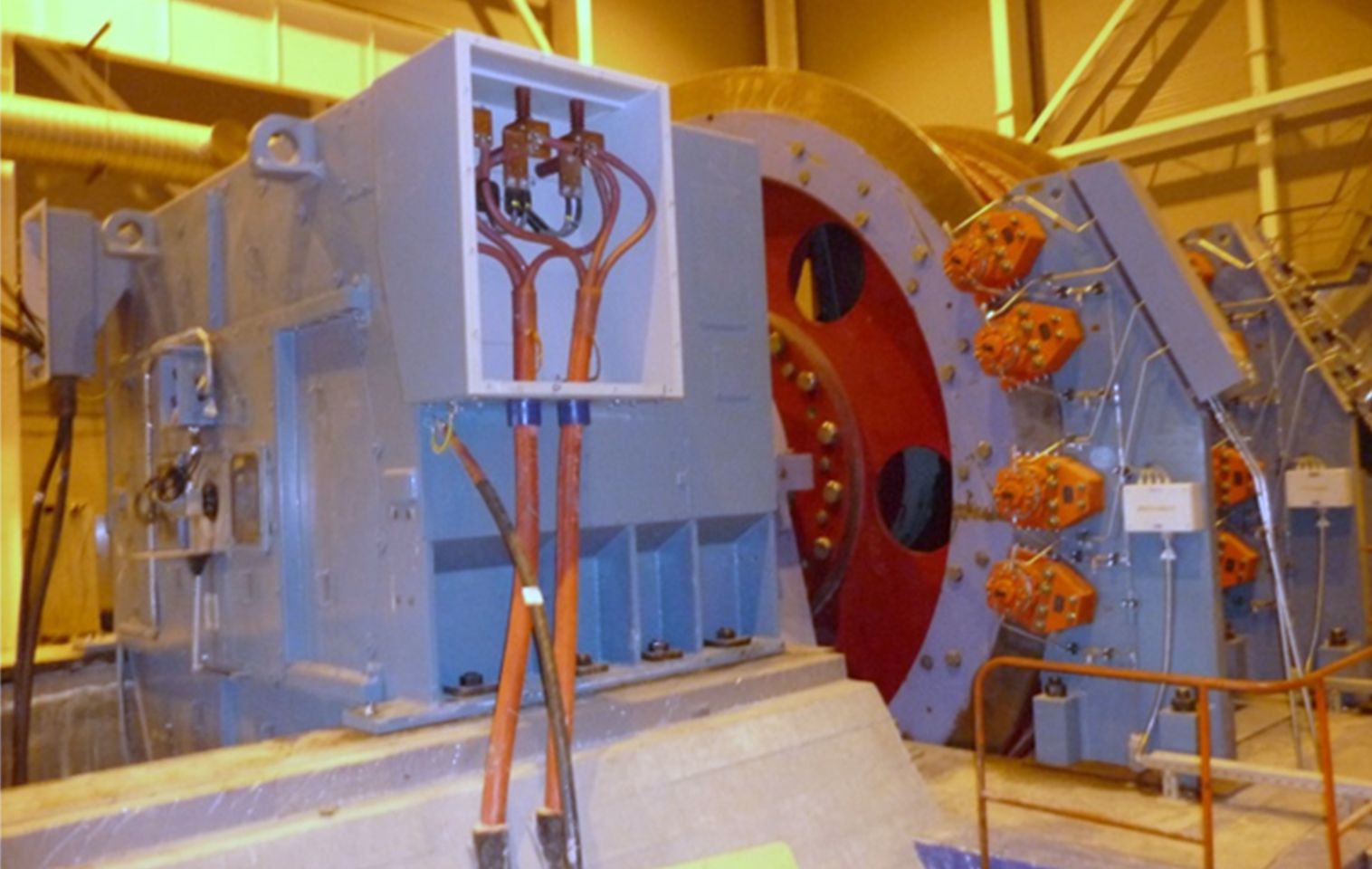

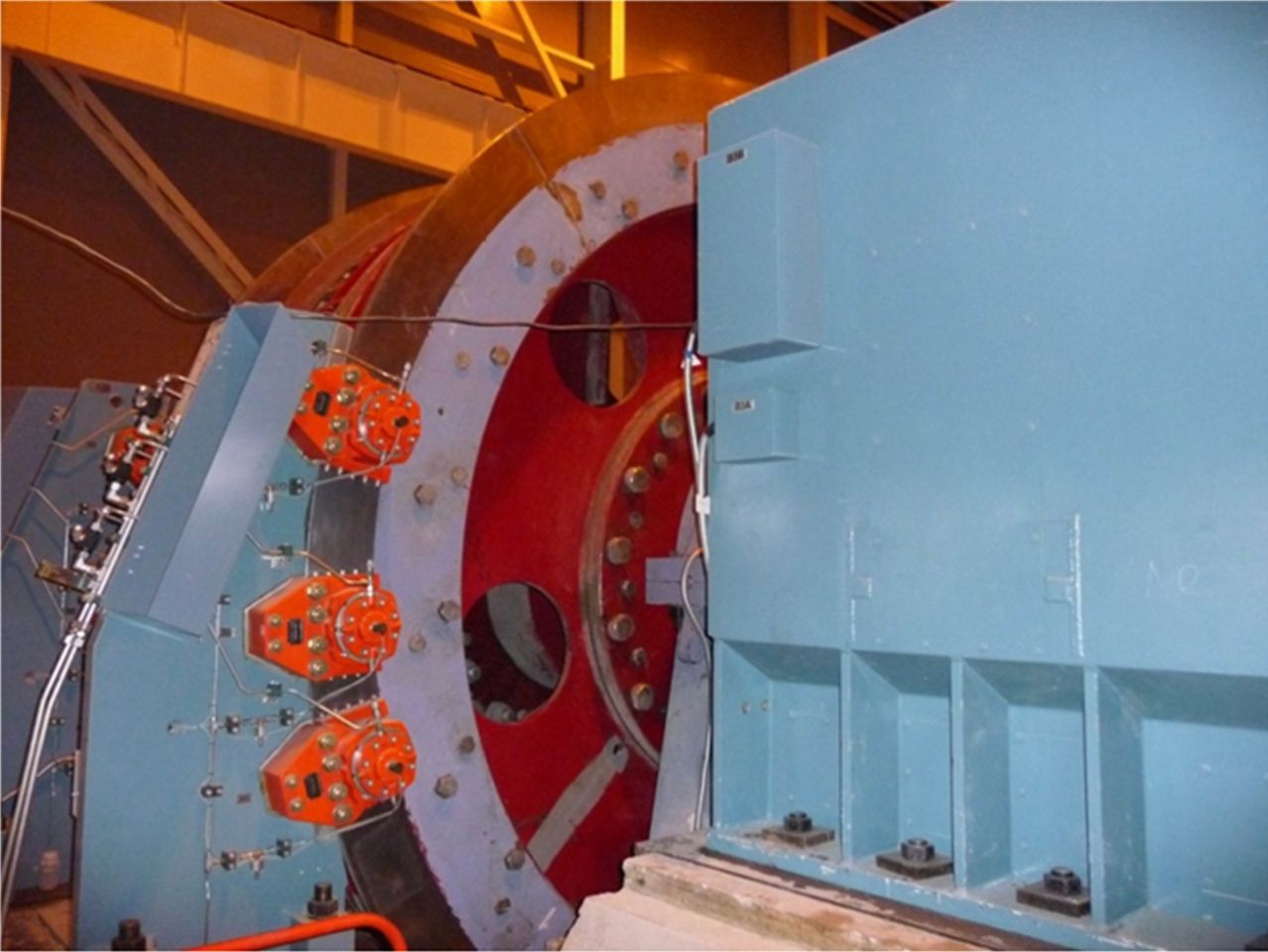

The hoisting machine is equipped with a braking system:

- disk brake system (standard, designation -D);

- radial-cavity brake system (on customer request).

According to the connection principle with the drive motor, hoisting machines are made of:

- connection by means of a gear coupling (a slow-speed electric motor is used);

- gear drive, designation –R;

- cantilever drive (uses a slow-speed motor), designation –K.

An example of type designation and construction features of a drum hoisting machine: 2C-3,5×2,4-RD – two-drum, with a drum diameter of 3.5 m, width of each drum 2.4 m, gearbox electric drive and disk brake.

An example of type designation and construction features of the multi-rope hoisting machine: CShN-5×6-KD – with a pulley friction diameter of 5 m, the number of ropes 6, the cantilever electric drive and disk brake.

Ordering of the shaft hoist is made on the basis of the filled questionnaire.

DOWNLOAD QUESTIONNAIRE

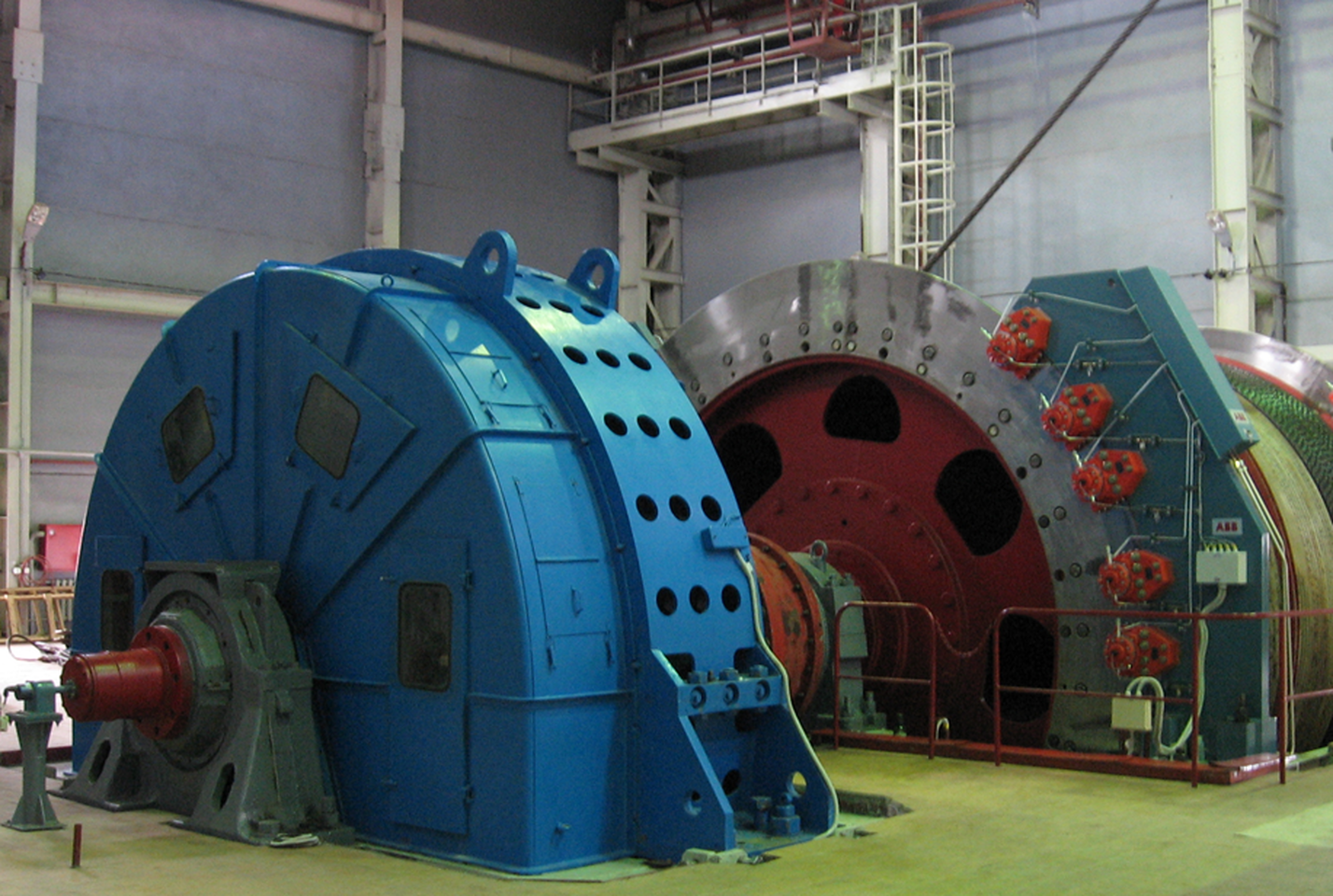

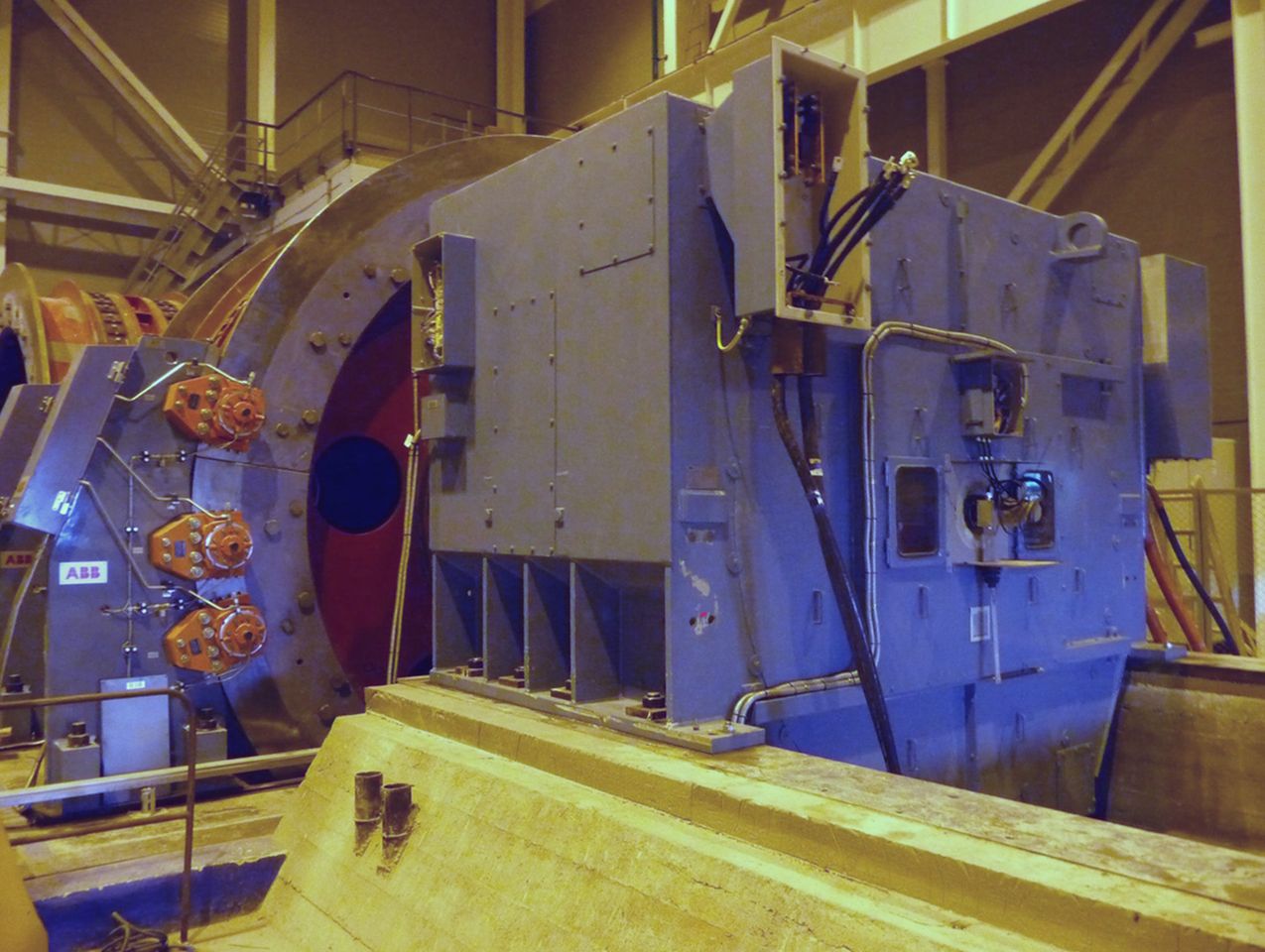

The design of the mechanical part of the machine is based on many years of experience in the manufacture of similar hoisfting machines by factories in Ukraine, EU countries and the MIDIEL Group, as well as the experience of their operation.

Design features of MIDIEL hoisting machines:

- the use of rolling bearings from leading manufacturers;

- bolted or welded drum design, use of European steel grades, modern welding technology, heat treatment and flaw detection;

- rational design of the root part, developed by means of end element modeling in the ANSYS software package;

- use of high-pressure multicomponent disc brake system with adjustable braking system based on SVENDBORG BRAKES A/S modules (Denmark).

The mechanical part is manufactured at one of the EU plants according to the design documentation of MIDIEL Group. Materials used for manufacturing of units and parts are subjected to strict incoming control. After manufacturing is completed, control assembly and cranking of the mechanical part is performed with participation of the Customer’s specialists.

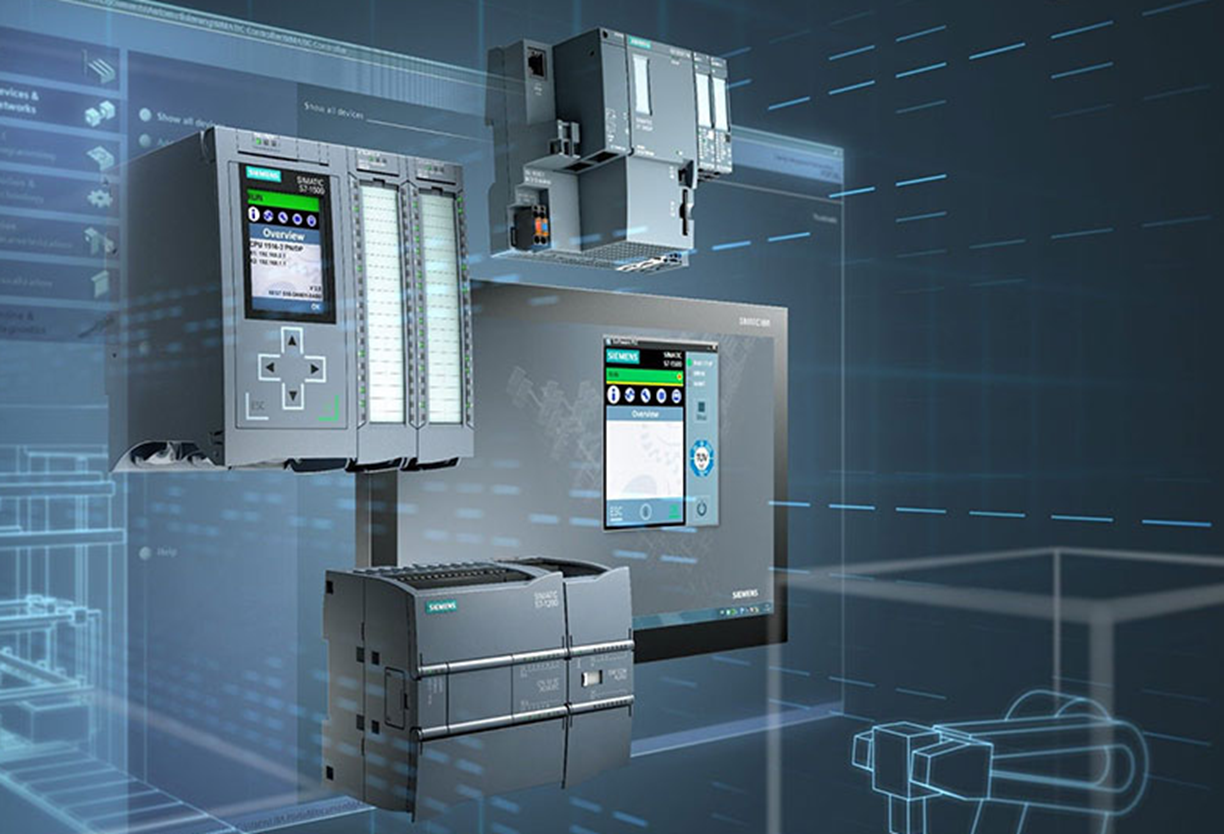

The lifting machine is equipped with electrical equipment, the composition of which is determined by the technical specification. Typical composition of electrical equipment:

- gear-type or gearless, AC or DC drive system;

- proprietary automated control and monitoring system based on modern Siemens programmable logic controllers with a developed “man-machine” interface system, including a parameter recorder;

- shaft signaling and communication system based on microprocessor technology using special trunk cables;

- other electrical equipment on request.

Electrical equipment from leading European and domestic manufacturers is used. When selecting the electrical equipment the customer’s preferences will be taken into account, the automatic control system of any other manufacturer can be used.